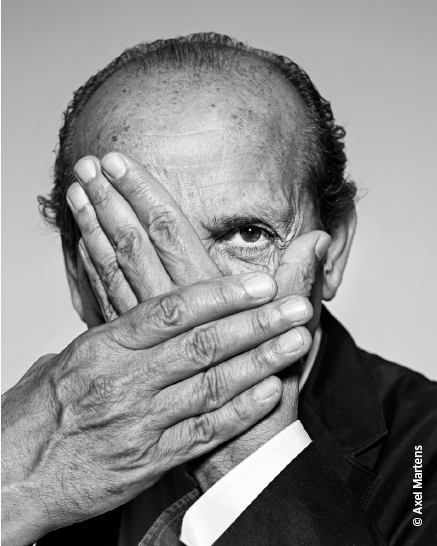

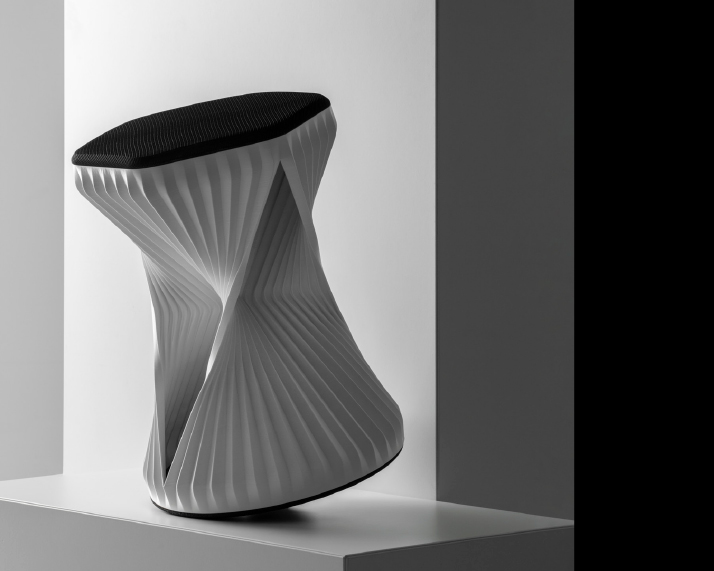

Iconic design meets groundbreaking production technology. In collaboration with the #wagnerdesignlab team, Hadi Teherani has placed ergonomic sitting in a completely new context and redefined the boundaries of design – with the help of the 3D printing process, 3-dimensional movable active stools are created in series production in our production plant in Langenneufnach, precisely adapted to every body size. Ecologically designed from Greentec Bio-Filament, a material made from 100% renewable raw materials that is biodegradable.

And the highlight – Wagner also offers a new ergonomic upgrade for all movement enthusiasts.

Printed at #wagnerdesignlab x thorsten franck

The low version is the perfect complement for tables in a classic working height. In its basic version, the W3D with comfortable upholstery is a real design highlight and an eye-catcher in every room.